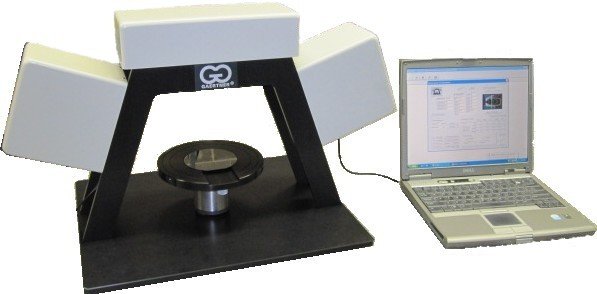

Gaertner manufactures highly precise easy to use laser ellipsometers for routine thin film thickness measurements.

Stokes Laser Ellipsometers

Stokes ellipsometers utilize a stable spectrally precise HeNe Gas laser to obtain the complete state of polarization of the measuring beam providing exceptional accuracy and precision. Gaertner helped pioneer ellipsometry and now offer high quality Stokes laser ellipsometers for routine measurements in the semiconductor, solar, chemical, biological and other thin film industries. They are easy to use popular alternative to overly complicated and less precise spectroscopic ellipsometers.

Ellipsometer Software - USB Upgrades for Gaertner Ellipsometers

Software and USB interfaced upgrades are available for older Gaertner ellipsometer models LSE, L116, and L115. Software programs LGEMP and LMOD for Windows give enhanced ellipsometer performance. Waferskan models L115 can be upgraded to 2D / 3D color mapping and visualization.

NIST Traceable Calibration Standards for Ellipsometers

Silicon wafers with a thermally grown silicon dioxide film so ellipsometers can be calibrated to high accuracy.

Priced at $995. Re-certify your standards for $795.